Konotop bent steel channel U-shaped, U-shaped, galvanized corner under the order, delivery (Metallobaza)

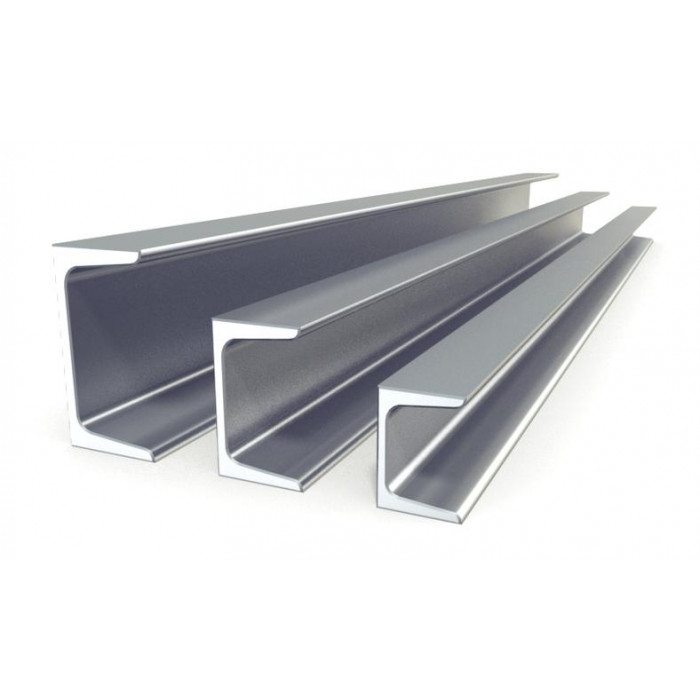

The bent channel is a steel profile, with a section in the shape of the letter "P". And refers to the type of rolled metal made from steel sheet. Like the hot-rolled channel, it has a U-shaped profile, but with more rounded walls due to production features, as well as a uniform thickness and more accurate dimensions. Also, its mass is less with almost identical strength characteristics, so the purchase of such a channel is more profitable in terms of costs than hot-rolled.

Equal-shelf bent channel

There are several options for classifying a bent channel. The decisive parameter is the width of the shelves, so there is an equal-shelf and unequal-shelf. There is also a classification according to rolling accuracy: high (A), increased (B) and ordinary accuracy.

Equal-shelf channel bent GOST 8278-83 ➤➤➤

Equal-shelf bent channel has two shelves of the same width. It is manufactured in accordance with GOST 8278-83. According to this standard, hot-rolled and cold-rolled steel, as well as high-quality low-alloy and structural steel, are used for the manufacture of bent equal-shelf channels.

GOST strictly regulates the parameters and technical characteristics of an equal-shelf bent channel. Bent equal-shelf channels according to their assortment have the following dimensions: wall height h from 25 to 410 mm, shelf width - b from 25 to 180 mm and wall thickness from 2 to 8 mm.

Channel bent unequal

Curved unequal channel GOST 8281-80 ➤➤➤

For unequal-shelf bent channels, the shelves have different sizes: the butt (small) and the feather (large). According to GOST 8281-80, unequal-shelf bent channels are made of hot-rolled and cold-rolled steel, as well as high-quality carbon low-alloy and structural steel.

The characteristics of unequal-shelf bent channels are strictly regulated by the GOST 8281-80 standards. So, bent unequal-shelf channels according to their assortment have the following dimensions: wall height h from 32 to 300 mm, width of the larger shelf - b from 22 to 160 mm, width of the smaller shelf b1 from 12 to 80 mm and wall thickness from 2 to 8 mm.

Production

Channels are made bent on special roll forming machines from sheet steel supplied in rolls and corresponding to GOST 11474. Due to the fact that the cold rolling method is used, this allows the production of this type of metal products in small batches.

The length of equal-shelf channels can be from 3 to 11.8 m, unequal-shelf - from 4 to 11.8 m. But at the request of the customer, it is possible to manufacture channels with a length of up to 12 m.

There are five length options:

Measured;

Measured with unmeasured segments;

Multiple measured;

Multiple dimensional with non-dimensional segments;

Unmeasured.

Application

Since the bent channel is made by cold rolling, it is not able to withstand such high loads as hot rolled. However, it is widely used as additional frame elements designed to reinforce the frame, as it has a lower mass, which reduces the load on the main structure, the cost and labor intensity of construction and installation work. It also lends itself well to processing, such as welding and forging.

The bent channel is widely used as a supporting structure in all types of construction, bridge building, the manufacture of frame and prefabricated structures, the manufacture of facades, walls and partitions, machine and car building, for the installation of racks, in the protection of hidden communications and for the manufacture of guides and ramps.

Characteristics and moments of resistance according to GOST

A bent channel, in comparison with a hot-rolled one, has a lower specific weight (with comparable profile dimensions), and, accordingly, lower rigidity and strength.

In detail, the mechanical and geometric properties of channels can be considered in the documents of the relevant GOST standards:

GOST 8240-97

GOST 8278-83

For example, let's compare the moments of resistance of hot-rolled channels 10U, 10P and bent 100x50x5:

The height of all channel profiles is 100 mm

Hot-rolled flange width - 46 mm, bent - 50 mm

Wall thickness of hot-rolled - 4.5 mm, shelves - 7.6 mm. The thickness of the bent channel - 5 mm

The cross-sectional area and linear weight of profiles 10P and 10U are 10.9 cm2. The bent profile 100x50x5 has an area of 9.09 cm2.

The modulus of resistance about the X and Y axes have the following values:

10Y: Wx=34.8 cm3; Wy=6.46 cm3

10P: Wx=34.9 cm3; Wy=7.37 cm3

100x50x5: Wx=26.68 cm3; Wy=6.2 cm3

It follows from this that the bent channel has the smallest values of the moments of resistance relative to both axes. This determines its scope.

Applications

A channel bent according to GOST 8278-83, the dimensions of which correspond to similar hot-rolled ones, should not be used as elements of highly loaded structures, especially those working in bending.

Bent profile isenjoy:

in construction for the manufacture of facing frames;

elements of modular structures;

for installation of ceilings, spans of warehouse and industrial premises;

installation of shelves, racks, etc.

It is also used:

in mechanical engineering;

shipbuilding;

aircraft industry;

automotive industry;

heavy and light industry.

Gates, fences, pipeline supports, guides of various lifting mechanisms are made from the channel.

A bent channel made of 09G2S steel can be operated without loss of its properties at low temperatures reaching -70 degrees Celsius. When applied to the surface of a zinc coating, its service life can be increased several times, due to the protection of the metal from corrosion.

The metal product is made from a strip by cold rolling on a mill with the ability to initially set the required standard size. The material and raw materials for production are cold-rolled, structural, low-alloy, hot-rolled types of steel, thus, depending on the raw material, certain physical and mechanical properties are attached to the finished product. You can buy a bent equal-shelf channel in Moscow from the Rent Metal company with additional processing - with the application of a protective anti-corrosion layer, order metal cutting to the desired size. Sheet thickness is from 2 to 6 mm, manufacturing accuracy according to class B is normal, C is high.

Technical requirements for the manufacture of bent channel

In the production of bent profiles, only steel of certain grades is used, in accordance with GOST. According to the standards, prints, rolled-in bubbles, individual nicks can be allowed on the surface of products, but cracks, scale, shells, dirt and multiple swellings are not allowed. The edges and ends of the workpieces according to the standard 11475 do not allow nicks, delaminations or a drawn edge. In a small number of nicks and dents are acceptable if they do not take the dimensions of the product beyond the nominal. Depending on the quality group, the products may or may not have cracks according to the standard. If the profile is of poor quality, cracks up to 10 mm long are allowed at the bend for a 2 mm thick profile. If this parameter is within 2-5 mm, then the length can be already 15 mm, and for a thickness of more than 5-20 mm and above.

Rolled metal products are produced on the machine, therefore, a decrease in the quality of products is possible only if the calibration of the rolls was performed incorrectly.

Regardless of the steel used in the manufacture of profiles, products can be mounted in two ways, both by bolting and by welding.

Bent steel channel marking

Such rolled metal products are marked according to the H × W × T scheme, where:

B - height, which usually ranges between 25 and 310 mm;

W - width, which according to the standard is in the range between 26 and 100 mm;

T - thickness, fluctuates between 2 and 6 mm.

A bent channel is made of steel. It is bent in the shape of the letter C. It is made of steel alloy. Channels are used to make durable structures in construction and in the home by welding them together. Channels are easy to machine. They can be cut with a grinder into sections of the required length. They are also easy to drill. Fastening bolts can be placed in the finished holes and the channels can be pulled together. In the production of channels, bent options and those with cracks and chips along the edges of the product are not allowed and are rejected. Channels lose their properties at low temperatures down to minus seventy degrees Celsius. They are easy to paint in any color. They are very strong and durable and will last for many years. When working with this material, observe safety precautions. Protect your hands with special gloves and your eyes with protective glasses.

No questions about this product, be the first and ask your question.