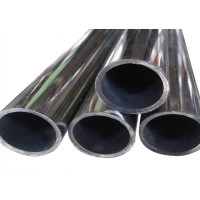

Kryvyi Rih pipe steel seamless cold-smoked, hot-smoked steel st20, st45 6-630 mm (Metallobaza) delivery, cutting

This type of rolled pipes is a more fundamental element of industrial and building structures. They are distinguished by maximum reliability due to production without welded seams. Such pipes are very resistant to both physical and mechanical impacts. All of the above guarantees increased performance characteristics. Seamless pipes GOST 8732-78 (assortment) and 8731-87 (technical requirements) are hot-deformed pipes. They are used in mechanical engineering, in the manufacture of various structures, for pipelines and even as a semi-finished product for all kinds of vessels. A wide range and clear technical requirements allow the consumer to choose exactly the pipe he needs and be completely confident in its quality. Seamless hot-deformed steel pipes are made of both carbon steel and alloy steel. The most popular steels are: 30KhGSA, 35, 20, 20Kh, 10, 09G2S, 45 and 40Kh. According to the standards, it is envisaged to supply pipes with a diameter from 25 mm to 820 mm. In this case, the wall thickness is 2.5-75.0 mm. The length of the pipes, according to GOST, is 4.0-12.5 m. But at the moment, pipes with a diameter of 32-550 mm and a wall thickness of 3.0 to 75.0 mm are produced. Seamless pipes GOST 8734-75 (assortment) and 8733-74 (technical requirements) are cold-formed pipes. Cold-drawn pipes are produced with a workpiece heated to a relatively low temperature, which is subsequently subjected to drawing, removing it and reducing the diameter and wall thickness. Unlike a "hot" pipe, it has a more accurate geometry. Like hot-formed pipes, cold pipes are made of alloy or carbon steel grades 30KhGSA, 35, 20, 20Kh, 10, 09G2S, 45 and 40Kh. According to standards, cold-formed pipes are produced with a diameter of 6 mm to 114 mm, and the wall thickness varies from 0.5 mm to 24 mm. Seamless pipes are rolled metal products in which there are no connections (joints, seams) along the entire length. Steel pipes are indispensable in many situations and are in demand on the market, despite the popularity of products made of polymeric materials. Types of seamless products

Stainless steel is a strong, reliable and durable material. Stainless steel pipes are widely used in everyday life and production. They are classified by the following features:

length: measured, unmeasured, multiples of size;

steel grades;

manufacturing method: hot-rolled and cold-rolled.

The manufacturing process is carried out at metallurgical plants from blanks. The difference lies in the heat treatment technology: cold-drawn pipes are processed after they cool down, hot-drawn pipes - in a red-hot state. The quality of the pipes is always at a high level, the products are created in accordance with the requirements of GOSTs.

Advantages of seamless pipes

Among rolled metal products, seamless pipes are the sales leader. The main advantages of these products include:

attractive appearance;

the possibility of manufacturing with different wall thicknesses;

tightness, resistance to temperature and pressure;

tolerance to aggressive environments;

safety and reliability.

The quality of the pipes ensures a long service life.

Application areas

Thanks to such properties as elastic deformation, strength, the scope of application of seamless pipes is quite wide:

Food and chemical industries. High throughput, purity allows transporting various liquids.

Oil producing, coal, heavy industry.

Aviation, space and defense.

Shipbuilding, automobile and tractor manufacturing.

Construction (supports).

Water and gas pipelines.

Interior design, furniture elements.

How and where pipes are used

Hydraulic systems in the modern world simply cannot do without such a detail as seamless steel pipes. These can be, for example, cylinders installed on trucks. The use of seamless pipes is becoming very appropriate in the energy sector. Wall thickness is the main parameter. It directly affects how long the entire structure can last, how long it can withstand rupture. Large sums of money can be spent on boiler repairs if the pipe stops functioning. Therefore, any investment in seamless pipes pays off in a short time.

Additional information about products

The high strength of these products allows them to easily find application, for example, in the processing and oil producing industries. Seamless steel pipes have a set of characteristics that make them quite popular products in many areas of production and industry. This is especially true for the construction and automotive industries. Even in the defense industry, seamless steel pipes have found their application - they help where chemical acttive and hazardous substances. After all, leaks in such cases can cause irreparable damage not only to the environment, but also to human health.

The most difficult issue is the choice of pipes for the manufacture of certain structures or construction of pipelines. When choosing, it is recommended to consider:

the possibility of using different types of pipes for a specific purpose;

technical characteristics;

pipe dimensions.

Seamless thin-walled pipes are used in many industrial and construction industries:

mechanical engineering,

oil industry,

chemical industry,

utilities,

construction,

furniture production,

interior design,

production of electrical lighting fittings,

production of refrigeration equipment, etc.

For each area of application, individual requirements are imposed on thin-walled pipes. Pipes differ in diameter (thin-walled pipes of large diameter), strength, and level of withstandable load. But each product must comply with the established state standard.

Thin-walled profile pipes will ensure the reliability and lightness of the structure

Thin-walled profile pipes are used to build lightweight structures that do not bear significant loads:

partitions,

fences,

public transport stops,

benches, gazebos,

furniture,

automotive parts,

products for industrial equipment

and other products.

Thanks to the use of thin-walled profile pipes, it becomes possible to create more complex structures. The product ensures their special strength and reliability.

Profile pipes are rectangular or square. This shape is ideal for the construction of residential and industrial buildings. Square and rectangular profile pipes are used as load-bearing elements. Flat walls ensure the convenience of laying such a pipe on a flat surface.

The use of profile pipes also allows you to reduce costs.

The absence of seams in the pipes allows you to evenly distribute the load and makes them indispensable and reliable. Seamless pipes lend themselves well to mechanical processing - they are cut, drilled, polished and welded. They are divided into thick-walled and thin-walled. Buy pipes only from trusted manufacturers who have a license to sell such goods in order to avoid buying counterfeits. They are pulled together in several pieces for storage and subsequent transportation. The pipes are highly durable and long-lasting, products made from them will serve you for many years. They are resistant to high humidity, high pressure, impacts and temperature changes. Seamless pipes are used in households to make supports for installing fences and weld frames and frames for future structures. When working with pipes, follow safety rules. Protect your hands with special gloves and your eyes with safety glasses to protect them from small metal particles. Cracks and holes in sheets are not allowed at factories, their edges must be smooth and free of burrs. Pipes come in different sizes. They are produced in diameters from six to six hundred and thirty millimeters. Steel is resistant to corrosion, very strong and durable. Before painting, this metal requires additional cleaning. Pipes are most in demand when laying water supply and gas mains. They are used to lay water mains. They are used to make supports for traffic lights, lanterns and road signs. Frames for greenhouses and orangeries are also welded from them. They are also made with different cross-section shapes: oval, square, rectangular and triangular. They are used to lay communications under highways and motorways. By diameter, they are divided into three groups: small diameter no more than one hundred and fourteen millimeters, medium diameter from one hundred and fourteen to five hundred and thirty millimeters and large diameter from five hundred and eight millimeters and above. Pipes with a diameter of two hundred and seventy-three to three hundred and twenty-five millimeters are used for buildings: water supply systems, heating and gas supply. Gas pipes must be carefully painted in bright colors, for example, yellow. Some furniture parts are also made from these pipes: legs for bar stools and tables. Small diameter pipes can be used to weld a frame for an outdoor table or bench. Seamless pipes are more resistant to leaks than those made using the seam method.

No questions about this product, be the first and ask your question.

-700x700.jpg)

-200x200.jpg)