Matviyiv (Pavlograd) circle calibrated steel 6-350 mm st20, st45, 40X, R6M5, 20X13, 08X18H10T (Metallobaza)

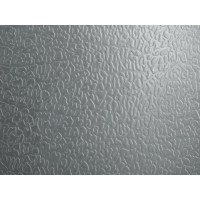

The calibrated circle is a kind of rolled steel and is a round bar. For the manufacture of such material, the technology of cold drawing with the use of hot-rolled raw materials is used. Outwardly, the products are very similar to steel bars, but they are distinguished by evenness and accuracy. A calibrated circle serves as a workpiece from which various parts for mechanisms, bolted joints, studs, shafts, etc. are made. That is why strict accuracy requirements are imposed on such a material. The main feature of the calibrated wheel is high geometric accuracy, as well as improved surface quality and strength. Rolled products can be produced in one of two ways: cold rolling method - consists in passing the workpiece through the rolls of the roughing and finishing stands, which helps to reduce the cross section. A similar technology is used for the production of hot-rolled circles, the only difference is that the rolled products are not preheated; drawing a hot-rolled bar through a die having a smaller cross section than the billet. This method is also called drawing. The resulting calibrated wheel can be subjected to auxiliary processing, including polishing and grinding in order to reduce the level of roughness and improve accuracy. The most popular is the method of manufacturing a calibrated circle by drawing, which makes it possible to obtain the most accurate dimensions with giving the surface special properties. The rods obtained using this technology have strength and elasticity and are used in the following areas and fields: Oil refining and gas industry. Machine-building. Machine tool. Construction of fences and gates. The reasons for the popularity of products are related to the fact that they do not need additional machining. This reduces the financial cost of using processing equipment. Thanks to a special technology, the output is high-precision products that are devoid of all types of flaws on the surface. The advantage of calibrated steel is its long service life. The positive technical properties of this material make it possible to use it in various fields and industries, and even in aggressive conditions. Specifications The calibrated wheel is obtained according to the GOST 7417-75 standard, which provides for the following features: production of rolled products with three types of surface quality - A, B and C (medium, high and increased accuracy); four varieties of quality: h9, h10, h11 and h. Production is carried out using various grades of steel. For this, alloyed, low-alloyed, as well as carbon and high-carbon steels are used. The length of the bars varies from 1.5 to 6.5 meters, and if it is necessary to obtain large-sized blanks, their production is carried out by special order. The product has the following technical features: Round section in the form of bars. The cut is made at a right angle. Section diameter — from 5 to 100 mm. According to GOST 7417-75, only a slight deviation is allowed in the range from 0.1 to 0.3 mm. Production material - different grades of steel, which are resistant to corrosion, temperature extremes and mechanical stress. Delivery of calibrated wheels is carried out in bays, if their cross section does not exceed 25 mm. If the rental is more than this value, then it is delivered in measured or random length. The blanks are marked with a diameter, the grade of steel used and the type of strength. Wear resistance determines the possibility of using rolled products to obtain various parts operated under conditions of increased loads. The cost of production is influenced by such factors as steel grade, rolling accuracy, quality, diameter and length. Outwardly, a calibrated circle is similar to an ordinary steel bar, only more even, accurate. In fact, he is what he is - a calibrated round bar. A simple bar, even made according to state standards, allows quite significant deviations in geometry, in surface accuracy. Accordingly, it is less demanding in terms of packaging, storage, and transportation. The circle calibrated is used as preparation for details of mechanisms, for bolts, hairpins, shaft and other products. Therefore, the requirements for the accuracy of its execution are higher. It is made from the same hot-rolled bar by additional rolling or drawing. At the same time, special attention is paid to the quality of the geometry, the absence of deviations. The raw material can be both carbon and alloy steel, including stainless steel. The same requirements are imposed on the quality of raw materials as in the manufacture of conventional bars. In some cases, the surface of the circle is additionally polished, as a result, an almost mirror surface is obtained. This variety is popularly called "silver". However, in any case, the standards require that the products be protected with oil from corrosion. An exception is made only for a stainless steel circle; oil can also be dispensed with by agreement with the customer.

Features of production and delivery

You can buy a calibrated circle of various sizes made of steel of various grades. The diameter varies from 3 to 270 mm and more. With a size of up to 5 mm (and with the agreement of the customer - up to 25 and even more), the circle can be supplied in coils. If the diameter exceeds this figure, then it is customary to manufacture rolled products in rods of measured and non-measured length.

The rods are supplied bundled, each bundle must be marked. In particular, the diameter of the rod, steel grade, type of manufacturing accuracy (high, increased, normal accuracy) are indicated.

The length of the rods can be from 1.5 to 6.5 m depending on the type of steel. If necessary, you can buy a calibrated circle cut into pieces of the required length. It is worth remembering that the state standard assumes the absence of burrs and bends. A calibrated steel circle is made by cold rolling or drawing. It is used to turn various parts on lathes from this round blank. Various tools are made of steel: screwdrivers, wrenches and adjustable wrenches. Rods are made from one and a half to six and a half meters long and from three to two hundred and seventy millimeters in diameter. If the diameter of the circle is up to five millimeters, it is packed in coils. Circles with bends and burrs are not allowed in production. The surface must be smooth. The circles must be even and of the same length. When working with circles, protect your eyes with special glasses and your hands with protective gloves. This material is easy to process. It can be sawed, drilled and welded. The circles are packed in coils of several pieces, of the same length. Steel is a very strong and durable material. Products made of this metal will serve you for many years. The circle is called calibrated because it is very accurately measured in length and diameter. Higher requirements for accuracy are imposed on them in comparison with ordinary circles. Some circles are additionally polished in order to obtain a mirror surface. The surface of the circles is coated with oil to protect against corrosion. In mechanical engineering, the railway industry and shipbuilding, a large number of different parts are made of steel. The price of circles depends on the grade of steel from which they are made, the presence or absence of a mirror polished surface and the amount of impurities in the steel itself. Circles are used in construction and at home as supports for fences and railings. The quality of the surface of the circles is divided into three types of accuracy. A - medium, B - high and B - an increased level of accuracy of the surface of the circle. In the diameter of future circles, minor deviations are allowed within the range from zero point one to zero point three tenths of a millimeter. You should buy steel circles only from trusted manufacturers to avoid low-quality and defective goods.

No questions about this product, be the first and ask your question.