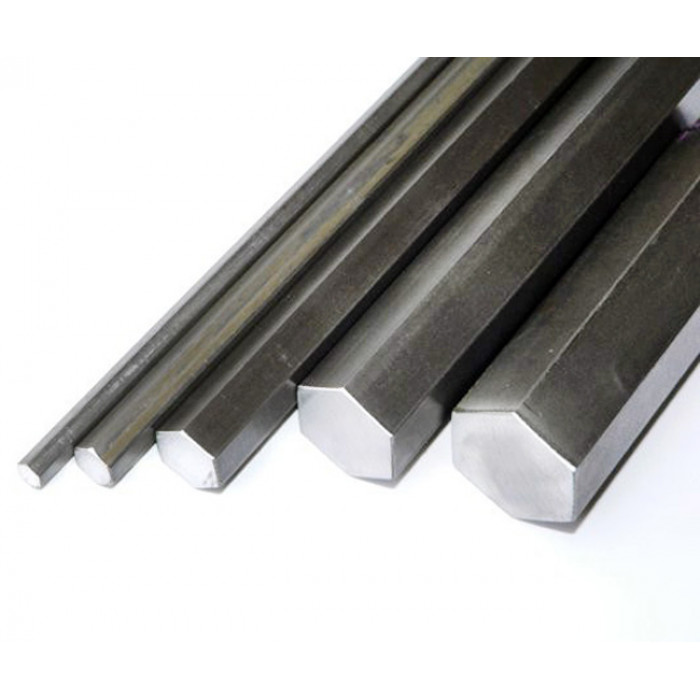

Poltava hexagon steel calibrated 8-75 mm st20, st45, 40X, 30HGSA (Metallobaza) delivery, cutting

Steel hexagon - This type of assortment is a fairly common material in construction and heavy engineering. Its application is mainly related to fastening material, such as screws, nuts, bolts. A steel hexagon is also used to create decorative structures. When erecting structures such as technological stairs and railings, balcony railings, and observation deck railings, a hexagon is often one of the main materials.

The steel hexagon is made from high quality carbon and alloy steel, which includes nickel, manganese and chromium. The steel hexagon is made in accordance with GOST 1435-99.

The hexagon is made on high-tech equipment. There are two ways to manufacture it: calibrated and hot-rolled method. Hot-rolled hexagon is produced in sizes from 8 to 100 millimeters. A calibrated hexagon is made of stainless steel, ranging in size from 3 to 100 millimeters.

Classification of hexagons

Depending on length:

Measured;

unmeasured;

Multiple measured.

According to the purpose of the hexagon, depending on the scope of its further use, a certain type of steel is used in the manufacture.

Hexagon rolling accuracy:

Normal - "B";

Increased - "B".

Depending on the percentage of chromium, nickel and manganese. This is also important when choosing a hexagon.

Consider the type of finish and surface quality of the hexagon:

Calibrated - GOST 8560-78;

Hot rolled - GOST 2879-88;

Hexagon rolled steel

Forged.

The quality of the composition of the steel hexagon may also differ:

Just quality;

High quality.

Material condition:

Not subjected to heat treatment;

Heat treated;

Hard-worked.

The post-processing type of the steel hexagon is also different:

Cold type machining;

Hot pressure treatment;

Cold drawing.

Types of steels for hexagons

Depending on the application, the material for the manufacture of hexagons differs in its characteristics. There are such types:

Classification of steel hexagons

Structural alloyed;

Structural low-alloy;

Structural carbon general purpose;

Structural increased machinability;

Carbon quality;

Corrosion resistant;

Heat resistant;

Stainless.

Characteristics of a steel hexagon

Resistance to high temperature loads;

Easy weldability;

Long service life;

High resistance to mechanical damage and low wear;

Immunity to inorganic and organic substances, acids and moisture.

Separate advantages have a stainless steel hexagon appearance. For its production, special grades of hardened steel are used. Most often, a stainless hexagon is made of the following steel grades: 08x18N10, 08x18N10T, 12X18N10T, 20X13, 40X13, 14X17N2 (EI 268), 45x14N14V2M (EI 69), 13x1N2MF (EI-961-Sh), 316L.

Stainless steel hexagon has special characteristics:

Corrosion resistance due to the presence of nickel and chromium in the composition;

Heat resistance;

High resistance to abrasion and stress;

Resistance to various aggressive environments;

High wear resistance.

The stainless hexagon is highly resistant to corrosion, so it can be used in the chemical and food industries, as well as in shipbuilding and mechanical engineering.

Applications of steel hexagon

Depending on the size of the steel hexagon and the properties used in its manufacture, the material is used in different areas and fields of activity:

If this material has increased resistance to aggressive environments, vibration and temperature effects, then this allows the use of a steel hexagon for the production and installation of equipment used in the food industry;

If it has high resistance to abrasion and a high level of strength, then such a steel hexagon is widely used as blanks for various fasteners (bolts, self-tapping screws, screws, nuts, etc.) in shipbuilding and mechanical engineering;

Resistance to alkaline, acidic environments, as well as solvents makes it possible to use it for the manufacture of mechanisms and parts in the chemical industry.

Steel hexagon is distinguished by the grade of steel, it can be: alloyed, high-alloyed, complex alloyed steel hexagon, carbon tool and stainless steel.

Hexagon distinguish:

with heat treatment (annealed, normalized, high-tempered ornormalized with high tempering) or without it, as well as hard-worked steel (strengthened at a temperature lower than the recrystallization temperature - with a special finish and calibrated);

according to the content of chromium, copper and nickel in mass fractions, depending on this, there is high-quality steel, high-quality and special quality.,

according to the method of final processing: for cold drawing and mechanical processing, for hot processing with the help of pressure. The hexagon is produced calibrated and uncalibrated.

The calibrated hexagon GOST 8560 has a more precise geometric shape, and if further processing of the rolled product (threading, turning, for example) and a product with more accurate parameters is necessary, then it is better to use calibration. parts manufacturing process. The advantage of calibrated metal is that there is no scale on its surface. The absence of it facilitates further cleaning of parts, more precise sizes and shapes are obtained. Also, during forging, stamping, scale is not pressed into the metal, which increases the durability of rolls and dies. Rolled products without scale are less susceptible to corrosion, all this increases the strength of the hexagon and allows this rolled product to be stored in warehouses for a longer time. Calibration has one significant minus - a high cost, compared with an uncalibrated version. For the production of such a hexagon, carbon and alloy steel are used. Calibrated rolled products are produced by cold drawing of a conventional hexagon.

A 12 mm hexagon has a weight of one meter - 0.979 kg. Hexagon 14 weighs: 1.330 kg per meter, Hexagon 17 - 1.960 kg per 1m.

The properties of hot-rolled products are regulated by GOST 2879-88. According to the standard, the assortment of hot-rolled steel hexagon includes products with an inscribed circle diameter of 8-100 mm, with rolling accuracy "B" (increased) or "C" (normal). At the request of the customer, manufacturers can produce products of large sizes.

Hexagonal calibrated steel is produced in accordance with GOST 8560-78 from hot-rolled billets by cold rolling or drawing. The main difference between calibrated products and hot-rolled products is improved surface quality and dimensional accuracy. Calibrated rolled products from free-cutting steels are used in the production of tools for high-speed machining.

Classification of hexagonal steel by size

The size of products is characterized by the diameter of the inscribed circle (the distance between parallel faces). In practice, this size coincides with the number of the key suitable for unscrewing / tightening fasteners. A steel hexagon is a steel product with a hexagonal cross-section. Various car parts and repair tools are machined from it: screwdrivers, wrenches, anchors, bolts, screws, chisels, gouges and taps. When buying it, pay attention to the manufacturer, they must have a license to sell such goods. This will allow you to avoid buying a low-quality product. It is resistant to rust, temperature changes and is very durable. Hexagons are easy to process - they are cut, drilled and welded. When working with them, you should follow safety precautions - protect your hands with special gloves and your eyes with safety glasses to avoid small particles getting into them. They are made from two to six meters long. Calibrated hexagons are made of stainless steel with a diameter of three to one hundred millimeters. They are used to make fasteners: screws, nuts and bolts. Due to its high resistance to aggressive chemical environments, it is used to make various parts and mechanisms that are used in the chemical industry.

No questions about this product, be the first and ask your question.