Rivne steel mesh, black, bronze mesh, galvanized mesh delivery (Metallobaza)

The bronze mesh is a woven mesh fabric with a dark golden hue. BrOf 6.5-0.4 is used as a raw material for its manufacture. The production of products from this material is a technologically complex process, so its cost is higher than analogues.

Bronze metal mesh is in demand due to its performance characteristics:

Strength to mechanical stress, namely stretching

Corrosion resistance

Electrical conductivity

wear resistance

Plastic

Does not spark on contact with metal

Environmental Safety

Duration of operation

Brand BrOf 6.5-0.4 is used to improve the properties of finished products by alloying with tin and phosphorus.

Areas of use

The bronze mesh is relevant for solving industrial-scale problems such as the separation of bulk instances and the filtration of liquid and gaseous substances. Woven fabric is in demand in the chemical, medical and food industries.

Anti-corrosion products are indispensable in mechanical engineering, shipbuilding and aircraft building. Demanded in electrical engineering.

The aesthetic properties of bronze mesh have made it one of the favorite materials for designers. Hardware decorate the interior and exterior.

The bronze mesh is made of bronze tin-phosphorus wire, which is characterized by increased strength and pronounced anti-corrosion properties. Due to its resistance to aggressive substances, the bronze mesh can be used as a filter element for various gases and liquids.

This is a woven type product - the wire in the mesh is intertwined, as in a fabric, as a result of which a metal sheet with cells is formed. Weaving can be of two types - linen and twill.

There are three types of mesh according to manufacturing accuracy:

normal accuracy (N);

high accuracy (B);

control accuracy (K).

There are many standards for the production of this mesh:

GOST 6613-86: Woven wire mesh with square mesh,

TU3651-026-00279597-2005: Bronze woven mesh of micron and medium sizes,

TU13-0281036-06-89: Nets woven from wire of non-ferrous metal alloys and corrosion-resistant steel for special purposes,

TU13-0281036-08-89: Twisted meshes woven from wire of non-ferrous metal alloys and corrosion-resistant steel,

TU13-0281036-11-90: Triple woven nets,

TU13-0281151-20-89: Single meshes woven from wire of non-ferrous metal alloys and corrosion-resistant steel, etc.

Grids bronze on manufacturing accuracy subdivide:

normal accuracy - N,

high precision - B,

control - K.

For the manufacture of grids of control, high and normal accuracy, bronze wire of the BrOF 6.5-0.4 brand is most often used.

On the surface of the wire there should be no traces of broach, cracks that affect the size of the sides of the cells, as well as captivity, sunsets and scale. Tempering colors are allowed.

In the manufacture of nets, plain and twill weaves are used.

Bronze meshes are used for filtering liquids or gases, for separating crushed materials by grain size, for controlling various materials by particle size during crushing, grinding and enrichment, etc.

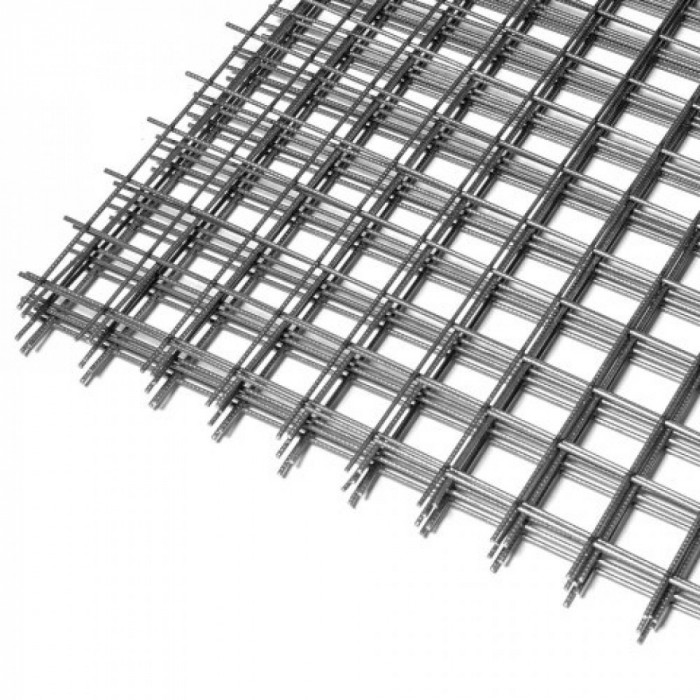

Where is welded mesh used?

For example, the company offers welded mesh for the following applications:

reinforcing - typically made from corrugated low-carbon steel bars and used to reinforce various reinforced concrete structures during construction;

masonry - usually produced in rolls and used to strengthen plaster and brickwork, as well as some types of reinforced concrete structures (in fact, it is a kind of road mesh);

road - serves to strengthen concrete / asphalt road surfaces and prevent the formation of growing cracks, it is especially effective on unsteady soils, it can also be used to reinforce concrete screeds and self-leveling floors in construction;

Remarks on the material of the meshes and their specific features

It is important to note that various grades of steel can be used as the base material for metal meshes, and in some cases it can be stainless steel, however, such products are very expensive and, as a rule, have a very specific scope. Canned meshes should be noted separately: in them, the elements used previously pass through a special beading device / machine, which gives them an alternating multidirectional bend, usually a much smaller pitch (unit mesh size) of the future mesh. Due to this, canned meshes acquire additional bending strength, which leads to the use of such meshes in screens and other screening devices, as well as where additional strength is required from the product compared to conventional meshes.

Subject interestedthe nomenclature of metal meshes, the reader will be able to find basic information about them in the selection of current GOSTs: for example, GOST 2715-75 contains additional information about those varieties that are not included in the brief description above. Also, GOSTs 3826-72, 5336-80, 23279-85 and 3826-82 are recommended for additional viewing.

Stainless meshes have more advantageous characteristics when compared with analogues. Let's take a closer look at the main advantages:

does not rust at high humidity or significant temperature changes;

long term of use without deformation of appearance;

easy to clean;

undemanding in care;

has impact strength;

breathable.

There are practically no drawbacks to this network. The only thing that can be noted is that the area of \u200b\u200buse of a particular variety is narrowly focused, because a certain structure of the structure or cell size is designed to perform only a certain task.

Summing up, we can add that due to the excellent performance properties, steel mesh can be purchased at low cost for various areas, be it construction, filtration, or reinforcement. Steel mesh is easy to machine, it is cut into pieces of the required size. When working with this product, you should follow safety precautions. Protect your hands with special gloves and your eyes with safety glasses. Buy mesh only from trusted manufacturers who have a license to sell such goods in order to avoid buying fakes. No bends or breaks in the mesh are allowed during production. During production, it is rolled into rolls and pulled together with wire for storage and further transportation. The mesh is highly durable and long-lasting, it will serve you for many years. The mesh is used to build fences in the country and vegetable gardens, as well as fences for ducks, chickens and other poultry. The mesh has the following properties: it is resistant to moisture and high temperatures. It is made by welding or interweaving thin steel rods together. The mesh is attached to the posts with wire, tightly screwing it to them. There is a steel plaster mesh, with its help they strengthen the surface of the walls during plastering works. The cannulated steel mesh has the form of strong rectangles or squares. Such a mesh does not roll up. Gates, cages, aviaries and fences are made of it. Masonry mesh is used at construction sites as a reinforcing material for pouring floors. Street benches can be welded from steel mesh, but they will be very inconvenient if the cell size is very large. For this reason, perforated sheets are often used to make benches. It is better to paint the steel mesh to give it additional protection from rust and to give it a more pleasant aesthetic appearance. Welded mesh is used to strengthen brickwork and concrete structures. Steel filter mesh is used for sifting bulk materials, for rough cleaning of water from pebbles and mule in the city water supply system. With the help of expanded metal mesh, sometimes they make grates in houses on top of heating batteries. It is also used to make various street furniture: tables, chairs and benches. Welded mesh is made of low-carbon or stainless steel. The mesh size of the woven mesh ranges from zero point five to twelve millimeters, and the wire diameter from zero point two to one millimeter. A roll can be up to forty-five meters long and from one to one point three meters high. Such a mesh is made by interweaving thin steel rods.

No questions about this product, be the first and ask your question.