Smila canned mesh, welded mesh, masonry mesh, corrugated, production (Metal base)

Welded mesh is made in cards and rolls from low-carbon black and galvanized wire, from VR1 wire and from A3 fittings. The range of cells is from 6 to 200 millimeters and the diameter of the wire, reinforcement is from 0.4 to 18 mm. The grid welded in cards is easily used in works. Welded mesh includes: masonry mesh, road mesh, galvanized mesh in rolls, galvanized wire mesh VR1, welded mesh from low-grade wire, welded mesh from A3 reinforcement, welded mesh in PVC, welded stainless steel mesh. The scope of welded mesh is quite wide, it can be used in masonry, for monolithic construction, for installing welded mesh fences, for floor screed. The most common is a welded galvanized mesh for fences with cells from 25 to 50 mm.

Masonry mesh is a welded mesh that is used when laying brickwork. Depending on the technical requirements for an engineering structure, it can be made both from GOST 3282-74 wire, and from VR-1 wire, V500S reinforcing bars.

Also, based on the requirements for the strength of the structure, the requirement for the cell, the diameter of the bar varies. The smaller the cell and the thicker the wire, the greater the number of bars in the card, the heavier the mesh card and the greater the strength characteristics provided by the reinforcement of the masonry.

Masonry mesh, the price of which includes increased material characteristics, certainly wins in quality, which is important for specialized facilities. Often, when the requirements for masonry reinforcement are standard, standard material quality is required.

Masonry mesh, the price of which is ensured by 100% compliance with the declared cell dimensions, wire diameter, card (roll) sizes, to what the supplier indicates in the documents, is a profitable purchase. And the main criterion for us as a manufacturer in choosing partners for the distribution of our products. You can use measuring tools before buying, check the weight of the masonry mesh if you are alerted by the low price. This in 99% of cases indicates that there is a discrepancy. Or you can work only with trusted suppliers, such as our regular partners - Actitrade companies.

Depending on your requirements, for any type of responsibility of structures and structures in Belgorod, the ZMS Metal Mesh Plant has debugged the production of masonry mesh with the following capabilities:

Cell from 12.5x12.5 mm to 500x500mm

With wire diameter from 1.0 mm

Cutting: width from 0.2 m to 2.6 m

Length: any

Often in demand:

Grid masonry 50x50x3. This product is most in demand in cards suitable for brickwork: 2x0.38., 2x0.5

Grid masonry 50x50x4. This option is also most in demand in the option convenient for brickwork: 2x0.38., 2x0.5

Grid masonry 100x100x4. Economy option. Acquired by consumers at non-responsible facilities. Also, in order to save money, customers, together with ZMS specialists, develop a mesh according to a personal drawing, which may contain different longitudinal and transverse bars in diameter. Rectangular cells.

Mesh masonry in a roll "barrel" - a profitable and convenient solution. The roll is unwound for the entire length of the masonry at a given width. There are no overlaps, which are technologically necessary when arranging masonry using grid cards, saving time and money. You can buy masonry mesh at an affordable price in several cities of the Russian Federation from ZMS representatives. The production of this type of product is debugged in light and galvanized form.

The marking is applied to the label or to the mesh packaging. If a wholesale batch is purchased, the manufacturer or supplier is obliged to attach an accompanying sheet and a specification for the goods to the order. The sheet indicates the steel grade, mesh type, address of the manufacturer's facilities, recommendations for installation. The marking contains the dimensions of the cell, the diameter of the wire in millimeters and the dimensions of the product (cards or rolls) in meters.

Grids are metal and polymer. There is no universal material, as each presents its own pros and cons. If, for example, iron meshes were in the lead in terms of characteristics, plastic ones would disappear as unnecessary.

Metal meshes provide good wall quality, strength, low coefficient of thermal expansion. However, metal structures are subject to corrosion. When rust corrodes the wire, an empty space is formed in which moisture and air will accumulate. This reduces the service life of the structure and leads to the destruction of the building, so the average life of residential premises in which a metal reinforcing part is used is 50 years (sometimes 100).

Also, the metal makes the structure heavier. Today, metal mesh is the standard, which occupies 80% of the market for reinforced structures.

Welded meshes, as mentioned above, are the simplest in terms of manufacturing technology. In industrial enterprises, they are made by a machine, and quality control is selective. The chance of finding a defective batch is extremely small. At small enterprises, such nets are made by hand, so the quality is better, but the price is higher.

Galvanized grids provide protection against corrosion and aggressive environmental influences. Air has a detrimental effect on the metal, oxidizing it and creating corrosion on the surface. For laying foam blocks, non-metallic meshes with a low degree of load are also suitable. You can mount them directly on the glue.

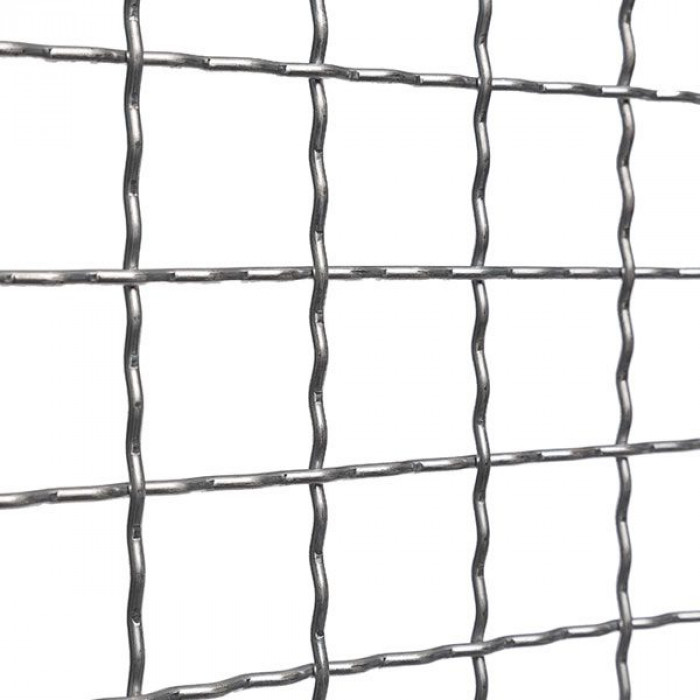

Canned corrugated

Corrugated mesh is a web of interwoven corrugated bars. Widely used in industry

where reinforced fencing is needed, protection of equipment and its individual components,

for reinforcing the walls of mine workings,

for crushing and screening of rock - in screens.

Welded mesh can have several types of galvanizing:

Galvanized, then welded (electrolytic galvanizing with a zinc layer of about 10 g/m2);

Welded, then galvanized (electrolytic galvanizing with a zinc layer of about 20 g/m2);

Hot-dip galvanized, then welded (hot zinc 35 - 50 g/m2);

Welded, then hot-dip galvanized, this is a welded mesh with increased corrosion protection (hot zinc is about 130 g/m2).

With an increase in the zinc layer, the resistance to corrosion of the welded mesh increases.

Welded mesh made from galvanized wire (galvanized, then welded) has a lower resistance to corrosion compared to the galvanized wire itself. Indeed, in order to weld wires together with electrodes, the welding place is heated to 1300 degrees Celsius - the melting temperature of steel. The boiling point (evaporation) of zinc is 907 degrees (melts at a temperature of 419.5 degrees). This means that during the welding process, the zinc will partially evaporate, especially at the welding points.

The mesh is welded, in the process of exposure to an aggressive environment, it starts to rust 2 times faster in the places of welding. Therefore, for longer operation, it is necessary to use a welded mesh with increased corrosion protection, namely in the coating.

In addition, polymer-coated welded mesh has been actively developed in recent years. This coating provides reliable protection in aggressive environments (sea air, nitric acids from manure, industrially polluted air, etc.). The vast majority of manufacturers produce such a green mesh. Often sellers indicate in the documents only the outer diameter of the wire, so you should always ask for the diameter of the steel core to be sure of its strength.

Welded mesh strength

The strength of the welded mesh is directly dependent on the size of the cell and the diameter of the wire. The smaller the cell and the larger the diameter of the wire (the more metal per square meter of the mesh), the stronger the mesh. Since the basis of the price of a welded mesh is the cost of the wire, some manufacturers underestimate the diameter of the wire and overestimate the mesh size. So they sell less durable welded mesh. In order to control the parameters of the welded mesh, it is enough to weigh the roll of this mesh and compare the weight per square meter of the mesh with the theoretical weight of the welded mesh. If the difference is more than 5%, then the quality of this roll is not all right. It can be shorter, lower, made of thinner wire or with an enlarged (weakened) cell. Cannulated mesh is used to build fences in the home. For example, to put a fence around the perimeter of a summer cottage or to allocate a small area for walking chickens, so that they are fenced off from the garden, a fine mesh is stretched. Such a mesh is not afraid of rain and is very durable.

No questions about this product, be the first and ask your question.