Smila plexiglass (acrylic) sheet, rod, tube, rubber conveyor belt, elevator belt, rubber bushing, RTI, rubber rings, dielectric mat

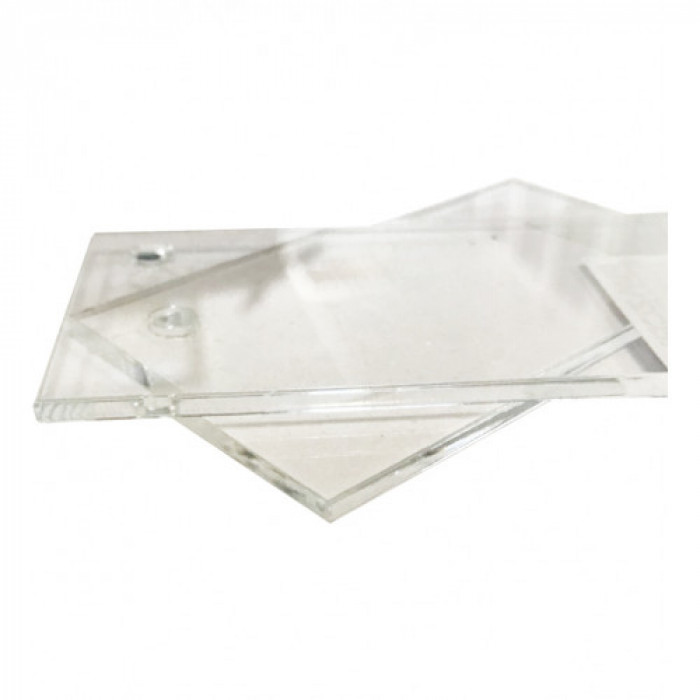

Sheet acrylic glass (plexiglass, acrylic) is transparent and colored sheets with a glossy, satin (matte) and textured surface, with a thickness range from 1.5 mm to 500 mm (acrylic plates). In addition, pipes and rods of various diameters are produced from acrylic.

Acrylic sheets are produced by extrusion and casting methods, in accordance with this, two main types of this material are distinguished - extruded and cast acrylic. And in a separate group, the so-called special types of acrylic can be distinguished, which have their own unique features.

Organic glass is a polymer of methyl methacrylate, an ester of methacrylic acid and methanol, polymerized to open the double bond between carbon atoms. The chemical structure of standard polymethyl methacrylic glass is the same for all manufacturers. To obtain a material with different specified properties: impact-resistant, light-scattering, light-transmitting, noise-protective, UV-protective, heat-resistant and others, its structure can be changed in the process of obtaining the material or components can be added to it that provide the necessary characteristics.

Main advantages

low thermal conductivity (0.2–0.3 W/(m K)) compared to inorganic glasses (0.7–13.5 W/(m K));

relatively high light transmission - 92%, which does not change over time, retaining its original color;

impact strength is 5 times greater than that of glass;

with the same thickness, plexiglass weighs almost 2.5 times less than silicate glass, so the design does not require reinforced supports, which creates the illusion of open space;

resistant to moisture, bacteria and microorganisms, therefore it can be used for glazing yachts, the production of aquariums;

environmentally friendly, does not form toxic gases during complete combustion;

has the ability to give a variety of shapes to products using thermoforming without violating the optical properties;

cuts almost as easily as wood;

sufficient resistance to environmental influences, frost resistance;

good transparency for ultraviolet rays, transmits 73%, while UV rays do not cause yellowing and degradation of the mechanical properties of acrylic glass;

stability in chemical environments;

electrical insulating properties;

subject to recycling.

Flaws

during pyrolysis without combustion, it releases a harmful monomer - methyl methacrylate;

tendency to surface damage (hardness 180-190 N / mm²);

technological difficulties in thermo- and vacuum forming of products - the occurrence of internal stresses in the bending points during molding, which leads to the subsequent appearance of microcracks;

flammable material (flash point +260 °C).

Plexiglas is obtained in two ways: extrusion and casting. Therefore, there are two types of plexiglass - extruded and cast.

The production method itself imposes a number of restrictions and determines some of the properties of the plastic.

Extrusion plexiglass (English extrusion, German Extrudiert) is obtained by continuous extrusion (extrusion) of the molten mass of granulated PMMA through a slotted die, followed by cooling and cutting to specified dimensions.

Block (English cast, the terms “cast”, “cast” have also become established in Russian) are obtained by pouring a monomer - methyl methacrylate between two flat sheets of inorganic glass and its further polymerization.

Many products made from these polymers can be replaced by products made from silicate glass, but plexiglass is much easier to process and form, and also has a lower density. This determines its advantage for the manufacture of various interior details, signs, promotional items and aquariums. Typically, inorganic glasses are used for the manufacture of optical fiber communications - quartz glass and glass based on germanium dioxide. Inorganic glasses, despite the cheapness of the material, are more expensive than plastic ones due to the complexity of manufacturing and the high cost of high-tech equipment for their production. Organic glasses are cheaper, but worse in terms of transparency, therefore, in non-critical applications in optical information lines of short length, polymer optical fiber is widely used.

Making a solvent adhesive for oneself by obtaining a monomer (methyl methacrylate) by distillation;

In plumbing (acrylic bathtubs), in commercial equipment.

PMMA has found wide application in ophthalmology: for several decades, rigid gas-tight contact lenses and rigid intraocular lenses (IOLs) have been made from it for several decades, which are currently implanted in the world up to several million pieces a year. Intraocular (that is, intraocular) lenses are known as an artificial lens and they replace the lens of the eye, cloudedas a result of age-related changes and other causes leading to cataracts.

Organic glasses as biocompatible materials. It is precisely because of such qualities as plasticity that biocompatibility has made it possible to replace inorganic glasses (for example, in contact lenses) in ophthalmology. In the late 1990s, silicone hydrogel lenses were created, which, due to the combination of hydrophilic properties and high oxygen permeability, can be used continuously for 30 days without removal from the eye. But these are not acrylic organic glasses, but a polymer optical material with its own characteristics.

Applications: lighting equipment (plafonds, partitions, front screens, diffusers), outdoor advertising (front glasses for boxes, illuminated letters, molded three-dimensional products), commercial equipment (stands, showcases, price tags), plumbing (bathroom equipment), construction and architecture (glazing of openings, partitions, domes, dance floor, three-dimensional molded products, aquariums), transport (glazing of aircraft, boats, fairings), instrumentation (dials, viewing windows, housings, dielectric parts, containers).

PMMA is used in micro- and nanoelectronics. In particular, PMMA has found application as a positive electron resist in electron beam lithography. A solution of PMMA in an organic solvent is applied to a silicon wafer or other substrate. Using a centrifuge, a thin film is formed, after which the required pattern is created with a focused electron beam, for example, in a scanning electron microscope (SEM). In the exposed areas of the PMMA film, intermolecular bonds are broken, as a result, a latent image is formed in the film. With the help of a developing solvent, the exposed areas are washed off. In addition to the electron beam, the PMMA layer can be patterned by ultraviolet and x-ray irradiation. The advantage of PMMA in comparison with other resists is that it can be used to obtain patterns with nanometer resolution. The smooth surface of PMMA can be structured by treatment in high-frequency oxygen plasma, and the structured surface of PMMA can be smoothed by vacuum ultraviolet irradiation.

Used as a material for making amber imitations

Types of conveyor belts

The classification of types of conveyor belts and their characteristics determines the scope:

General-purpose rubberized fabric sheets are used for transportation of lumpy, non-abrasive, low-abrasive and bulk materials, packaged goods at agricultural, light and processing industries. According to GOST 20-2018, they are made of rubber of classes A, I, B, are operated at temperatures from -45 ° C to +60 ° C and can be one-, two- and multi-layer. The frame traction pad is made of synthetic or combined polyester and cotton.

Rubber cable (mine) tapes are designed for mining enterprises. They transport coal, rock and rock masses, ores, salts and other minerals. The frame is made of brass-plated or galvanized non-twisting steel cables and pressed into an adhesive rubber layer. The characteristics of conveyor belts of this type are determined by GOST R 56904-2016.

Flame-retardant, heat- and frost-resistant tapes are designed for operation in difficult temperature conditions. For all three types of cloths, the thickness of the outer linings of the working surface is increased, and for the linings themselves, rubber of classes G (burning time is not more than 15 seconds), T (does not change properties when in contact with loads heated to 210 C) and M (does not collapse in frost) is used. ). The technical characteristics of flame retardant tapes allow them to be used in mines and coal mines, heat-resistant cloths - in glass, metallurgical, cement plants, drying lines, in the chemical industry. Frost-resistant fabrics are installed on conveyors of cooling lines and conveyors operating in open-pit mining and processing plants.

Food conveyor belts are used in the transportation of packaged and unpackaged products. To prevent the fabric from changing the taste, color and composition of products, it is made from materials that are resistant to high temperatures, fats and acids. It can be food-grade oil-and-fat resistant polyvinyl chloride (PVC), polyurethane and thermoplastic polyurethane, silicone, food-grade rubber, as well as rubber-fabric material coated with artificial felt and cotton. The main requirement for belts for the food industry is FDA certification. Like general purpose tapes, food webs are made with a frame of polyester-polyamide, polyamide, combined fabrics, although there are products without cord and with the inclusion of thermal paper.

For the transport of hot and abrasive materials in heavy industry, solid-rolled metal and mesh wire belts are used.

Classification of conveyor belts by structuresurfaces

The web material determines the type, shape, temperature, and other characteristics of the transported cargo, while the structural coating determines the operating conditions of the conveyor.

According to the surface profile, conveyor belts are divided into smooth, corrugated, chevron.

Smooth conveyor belts are suitable for conveyors with an inclination angle of up to 18 degrees (maximum) and are considered universal. Suitable for moving piece, bulk and packaged goods of various types.

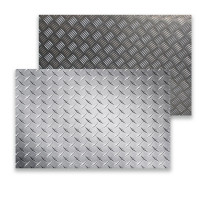

Conveyors with an inclination angle of up to 30 degrees are equipped with corrugated belts with notches or recesses that prevent the load from sliding. The surface profile can be diamond-shaped, ribbed, mesh, supergrip, etc.

Chevron sheets have ribs 6, 16, 25 or 32 mm high across the entire width of the belt. On conveyors with an inclination angle of 22 to 45 degrees, such ribs facilitate the movement of packaged, powdery, bulk cargo of different fractions. The pattern and height of the chevrons are selected according to the diameter of the conveyor drum, the fraction and moisture content of the materials.

No questions about this product, be the first and ask your question.

-200x200.jpg)