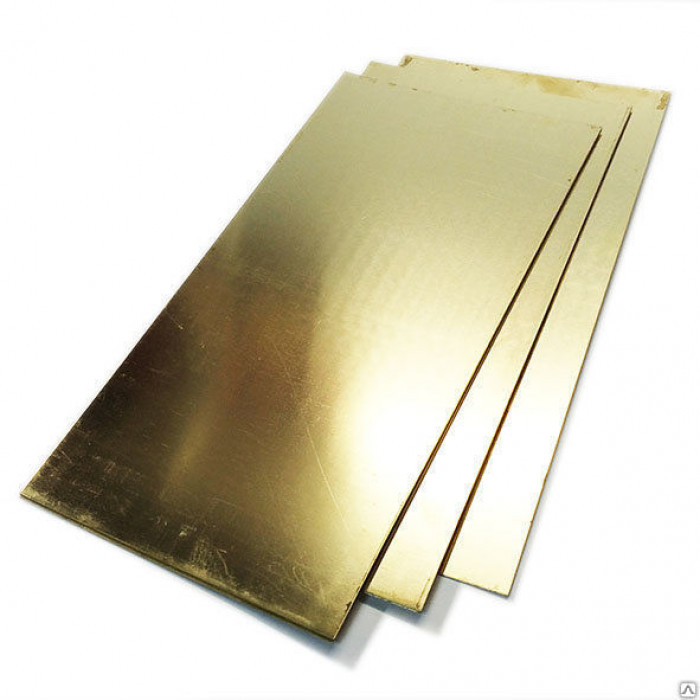

Ternopil sheet brass LS59-1, L63 600x1500mm, brass 0.4-45 mm, cutting, delivery

Brass sheet is a product made of a copper alloy, in which the main alloying element is zinc. The scope of this type of rolled metal is very wide, which is explained by the characteristics of brass, which is used for its production.

Main characteristics

Brass sheet can be produced by cold or hot forming. To obtain such a rental, manufacturers can use two types of brass:

multicomponent (in its chemical composition, in addition to copper (about 40%) and zinc (1–2%), alloying additives such as aluminum, tin, nickel and lead are contained);

two-component (contains in its composition only copper (60–97%) and zinc).

The popularity enjoyed by a brass sheet from modern manufacturers is explained by a number of advantages that distinguish such a product. Let's list them.

Ease of processing allows you to create blanks and finished products of almost any configuration from this type of rolled metal without significant labor costs.

The exceptional decorative characteristics of the brass sheet are not lost during the operation of the finished product.

On the modern market, brass sheet is presented in a wide range of thicknesses (0.5–25 mm), which allows consumers of such products to choose the material that best suits their requirements. All such products comply with the requirements of the regulatory document (GOST 2208-2007).

Products made of sheet brass are distinguished by high corrosion resistance and can be successfully operated in contact with even very aggressive media.

Additional advantages of using such a material include the fact that brass, sheet and other types of rolled products from which can be successfully used in a fairly wide temperature range (from -80 to +120 °), can be easily polished (this is especially important for decorative products) . Even complexly deformed brass products retain the unique structure of the original material and, accordingly, all its original characteristics.

Brass sheet, the requirements for the parameters and characteristics of which are stipulated by the provisions of GOST 2208-2007, does not resist wear well enough, but such a disadvantage of this product is compensated by a whole list of its advantages. In particular, this should include good workability by plastic deformation methods at any temperature, as well as good weldability using argon arc welding.

Where is used

Brass sheet, the entire assortment of which is stipulated by the provisions of GOST 2208-2007, is successfully used in almost all industries, as well as in the domestic sector. Almost no machine-building and chemical enterprises, plants of the energy and oil refining industries can do without products made from such material today.

Many products that use brass sheet are produced by cold profiling. If necessary, brass sheets are easily perforated; this procedure does not require expensive tools and special equipment. The decorative characteristics that distinguish this material make it possible to use it for the manufacture of elements of furniture and advertising structures, the design of facades of building structures for various purposes. The brass sheet can also be used to create design elements and advertising structures due to its low weight.

In the domestic sphere, when performing repairs and decorating premises for various purposes, brass sheet metal is also used quite actively. In recent years, due to the growing popularity of interiors decorated in a classic style, brass sheets are often used to decorate the inflow zone - a section of the floor directly adjacent to the fireplace.

Such an inflow zone, which is subject to more active wear than the rest of the floor surface, must also ensure the safe use of the heating device. At the same time, the inflow zone should be in no way inferior to the decorative characteristics of the fireplace itself, which often plays the role of the main element of the interior.

Brass sheet can be produced by cold or hot forming. To obtain such a rental, manufacturers can use two types of brass:

multicomponent (in its chemical composition, in addition to copper (about 40%) and zinc (1–2%), alloying additives such as aluminum, tin, nickel and lead are contained);

two-component (contains in its composition only copper (60–97%) and zinc).

The popularity enjoyed by a brass sheet from modern manufacturers is explained by a number of advantages that distinguish such a product. Let's list them.

Ease of processing allows you to create blanks and finished products of almost any configuration from this type of rolled metal without significant labor costs.

The exceptional decorative characteristics of brass sheet are notare lost during the operation of the finished product.

On the modern market, brass sheet is presented in a wide range of thicknesses (0.5–25 mm), which allows consumers of such products to choose the material that best suits their requirements. All such products comply with the requirements of the regulatory document (GOST 2208-2007).

Products made of sheet brass are distinguished by high corrosion resistance and can be successfully operated in contact with even very aggressive media.

Additional advantages of using such a material include the fact that brass, sheet and other types of rolled products from which can be successfully used in a fairly wide temperature range (from -80 to +120 °

), easy to polish (this is especially important for decorative products). Even complexly deformed brass products retain the unique structure of the original material and, accordingly, all its original characteristics.

Brass sheet, the requirements for the parameters and characteristics of which are stipulated by the provisions of GOST 2208-2007, does not resist wear well enough, but such a disadvantage of this product is compensated by a whole list of its advantages. In particular, this should include good workability by plastic deformation methods at any temperature, as well as good weldability using argon arc welding.

Pros and cons of brass sheet

The advantages of using brass sheet include its strength, corrosion resistance, ductility and aesthetic appeal. It is also a relatively inexpensive material. However, there are some drawbacks to using brass sheet, such as its tendency to tarnish, its relatively low melting point, and its tendency to be cold brittle.

Properties of round brass rolled products:

good workability by pressure in hot and cold conditions;

high mechanical properties;

beautiful colour;

comparative cheapness;

corrosion resistance in atmospheric conditions is average between the resistance of the elements that form the alloy, i.e. zinc and copper;

The electrical and thermal conductivity of brass is lower than that of copper.

Round brass rolling is used:

in metallurgy

instrument making

automotive industry

electrical engineering

power industry

mechanical engineering

telecommunications

in the production of electrical wires and cables

Brass sheet is an alloy of copper and zinc. When producing sheets at the factory, no chips or burrs are allowed on the edges of the sheets. Such sheets are rejected. They must be smooth, of the same size and thickness and without holes. Brass is easy to machine. It is easy to drill, weld and cut. When working with this metal, observe safety precautions. Wear glasses to protect your eyes. Use special gloves to protect your hands. Buy brass sheets only from trusted suppliers who have a license to manufacture this product. This will save you from buying low-quality and defective goods. Nowadays, the scope of application of brass is very extensive and is in high demand in many industries. Brass sheets are made in thicknesses ranging from zero point five to twenty-five millimeters. This metal does not lose its properties in a fairly wide temperature range, from minus eighty to plus one hundred and twenty degrees Celsius. Decorative elements are made from brass, for this its surface is carefully polished to a mirror shine. In modern private houses, a brass sheet is attached to the section of the floor on which the future fireplace will stand.

No questions about this product, be the first and ask your question.