Uzhgorod rubber products - cord, paronite, profile, raw rubber, technical plate, membrane, highway, conveyor belt, sleeve, sealant, packing, tube

Rubber products (RTI) are the most common parts applicable in almost all areas of production: in instruments and professional equipment - machines and units from workshops to agricultural ones. Rubber products are also often used in everyday life. This is a gasket in a water tap, a hose that supplies gas from a pipe to a stove, a seal in plastic windows, on a refrigerator door, and much more.

What are rubber products

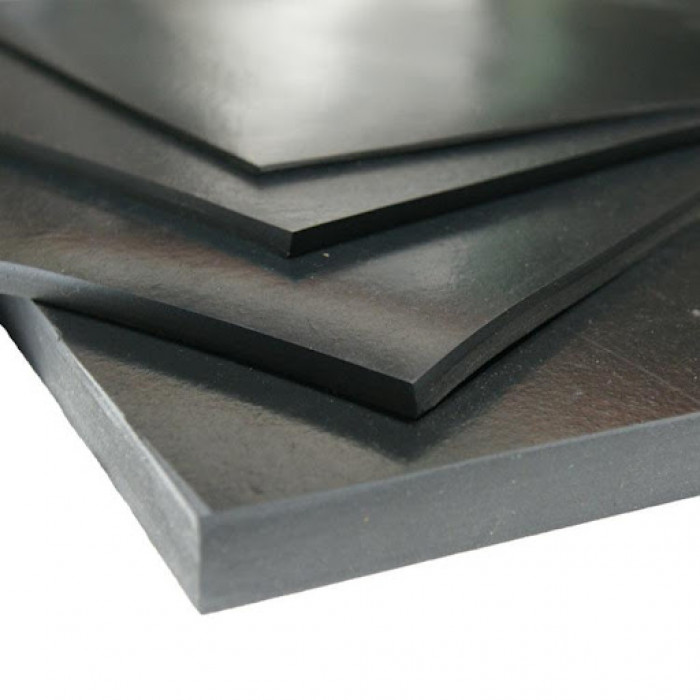

The production of rubber products is carried out from rubber of natural or synthetic origin. These are parts of various shapes and purposes, which are divided into two groups:

Molded - products of a certain shape: shock absorber, gasket, seal, bushing, ring, reinforced cuff, etc. They are made by forming raw rubber in a hydraulic press or by injection molding. Molded rubber products are produced according to standard templates or by individual order. There are about 30 thousand types of such products.

Unshaped - pipes, rubber sleeves, cords, etc. They are used in the automotive-aircraft industry and other areas. The production of non-molded parts is more difficult than molded parts. A mass of rubber is passed through a die, which has grooves in its inner part. This is how the product profile is formed. Then vulcanization is carried out by current, high temperature or ultraviolet radiation. Approximately 12,000 types of non-molded rubber goods are manufactured.

Rubber products are porous, reinforced - more durable, with the addition of silicone, paronite, etc. They are made from natural or synthetic rubber, latex, polyamide, polyvinyl chloride. They come in various diameters and sizes.

RTIs differ in properties:

oil and petrol resistance;

acid resistance;

resistance to high temperatures;

ozone resistance;

current conductivity, etc.

Rubber has protective properties that make rubber sleeves and tubes suitable for insulating, moving aggressive media through the system. Features of rubber products:

Their material after deformation takes its former shape at low loads. It is flexible, elastic, resistant to temperature changes.

Long service life.

Resistant to chemicals, gasoline.

Application

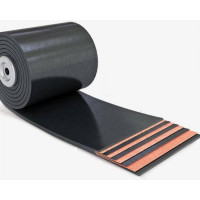

RTI serve as joint seals, heat and electrical insulation, and a sealing layer. Rubber is used to make belts that transmit rotational energy in various mechanisms: vacuum cleaners, machine tools, washing machines, etc.

Rubber products are used in many areas:

Aircraft construction and assembly of devices used in aggressive weather conditions.

Units of the chemical industry. Corrosive substances ply along the rubber sleeves.

Belts for conveyors.

Automotive. The design of many machine components contains rubber products - hoses, seals, seals, etc.

Pump building. Use rubber pumps, seals, sleeves and hoses.

During the construction of buildings, rubber bands seal the joints of the panels.

According to the production technology, rubber products can be

Molded rubber products are made in two main ways:

molding the raw rubber compound in a hydraulic press;

molding the raw rubber compound by injection molding.

Non-shaped rubber products - this includes various sleeves and hoses

Porous rubber products are a material characterized by a spongy structure. It is obtained by vulcanization of rubbers containing blowing agents or foam rubber.

Reinforced rubber products in terms of durability and reliability are significantly superior to non-reinforced rubber products.

Rubber products

Silicone rubber is a state-of-the-art organosilicon material that has unique properties that distinguish it from conventional organic rubbers. Silicone products work in conditions of significant temperature changes, have high impact resistance and durability

Fluororubbers - Fluororubbers are superior in chemical resistance to all known elastomers. Fluoroelastomers are resistant to mineral acids, aliphatic and aromatic hydrocarbons, various fuels, oils and greases

Rubber adhesive 88-SA, 88-NP - used for cold bonding of rubbers based on general purpose rubbers to metals, glass, concrete, wood, rubber, also for bonding linoleum to a wooden or concrete floor base

Paronite gaskets - paronite is used as a gasket material and as a sealant for connectors, more often in aggressive environments or at extreme pressure and temperature values.

A rubber compound is a composition of specially prepared rubber and other components, including stabilizers, fillers, volcanic agents.cations, plasticizers and so on.

Industrial rubber products are manufactured using modern equipment, which allows the production of large-sized and rubber-metal products. Qualified specialists of the company will solve the client's problems associated with the manufacture of new types of products - parts and profiles of various configurations. The strategic goals of the company provide for the use of the latest technologies, materials and equipment in the production.

The quality management system in place in the company complies with the requirements of the DSTU ISO 9001-2009 quality standard for the production of rubber compounds and rubber products, ensures reliable quality control at all stages of the technological process, and ultimately guarantees the high quality of the customer's order. Rubber products are easy to machine, they are cut into pieces of the required size. When working with this product, you should follow safety precautions. Protect your hands with special gloves and your eyes with safety glasses. Buy rubber products only from trusted manufacturers who have a license to sell such goods in order to avoid buying fakes. Holes and cracks in rubber are not allowed in production. If these are rubber sheets, they are packed and pulled together in several pieces for storage and further transportation. Rubber has high strength and durability, it will serve you for many years. Rubber is used in various industries: automotive, agriculture, railway and shipbuilding. Various seals, car tires are made of rubber. For everyday use, they are used to make hoses, seals for refrigerators, windows, taps and water pipes. RTI have the following properties: they are resistant to aggressive chemical environments and high temperatures. Rubber is used to make insulation in electrical engineering. Conveyor belts and transmission belts in machine mechanisms in production are made of rubber. Scrapers for the edges of the bucket of a snowplow are cut from rubber sheets. Porous rubber is made by vulcanizing rubber with an admixture of foam rubber. Rubber is also used to make seals for machines. Rubber is used to make parts that are divided into two main groups: non-molded products - various cords, pipes and sleeves and molded products - rings, bushings, gaskets, seals, shock absorbers, cuffs. There are about thirty thousand such products. Depending on the area of application, rubber products are: reinforced, porous, with admixtures of silicone and paronite. Rubber is very elastic, under light loads it does not deform and takes its original shape. Forms and mats for baking pies and potholders are made of food rubber. Due to its increased electrical insulation, rubber is used to make protective gloves, boots and mats for electricians. Soles for winter shoes are made from dense rubber. Shock-absorbing stickers for the doors of cabinets, wardrobes and chests of drawers are made from rubber, so that the doors do not get knocked down during the manufacture of furniture. Small hoses inside cars, through which machine oil and gasoline pass, are made from rubber. The inner tubes for tractor and car tires are made from rubber. In agriculture, various hoses for seeders, tubes for the hydraulic system of cultivators and other agricultural machines are made from rubber. Sealing rings for flow-through water filters are made from rubber, in order to avoid leaks during their use. There are about twelve thousand types of non-molded rubber products. In gardening, their rubber is used to make borders, which are used to fence and separate sections of the garden from each other.

No questions about this product, be the first and ask your question.