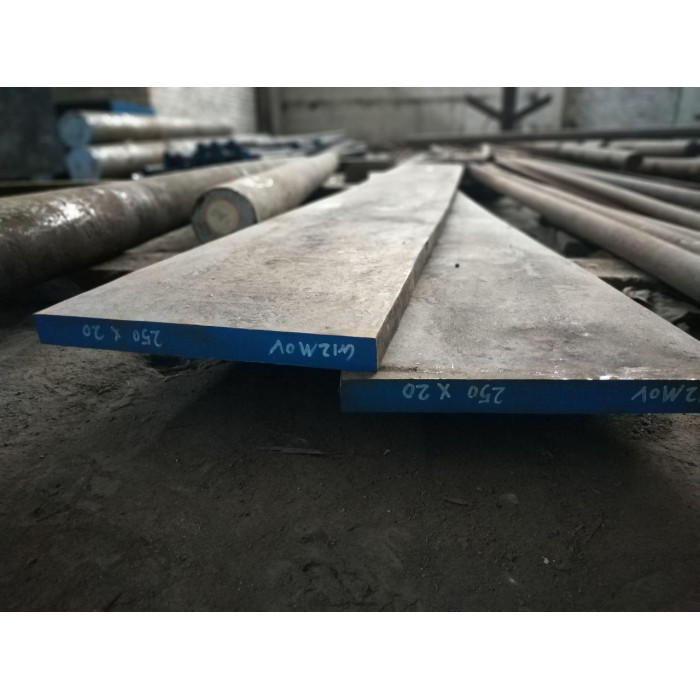

Zaporozhye strip X12, X12MF 2 - 600 mm, strip 65G, 30HGSA, R6M5, steel delivery and cutting

Grade class In the mechanical engineering industry, Kh12MF steel is considered the main grade. Characteristics of the material differ from other carbon tool grades in high structure density. This type of steel belongs to the class of tool stamped. For a long time, it was used only in the production of dies for bending and molding products. Since X12MF forged steel is highly resistant to external physical influences, it is used in heavy industry and engineering industry. h12mf steel characteristics reviews This steel is a high-quality material from which hunting knives are made. As evidenced by numerous consumer reviews, such cutting products are very durable and do not get dull for a long time, which is important for a hunter. The advantages of the material are taken into account by manufacturers using Kh12MF steel in the production of products. Properties The advantages of this steel grade include: high strength; heat resistance; hardenability; hardenability; wear resistance; manufacturability. The last property is estimated by craftsmen who process Kh12MF steel. The characteristics of the grade allow it to be processed using cutting, pressure and grinding procedures. Products of Mark X12MF are used in the manufacture of: profiling rollers with a complex shape; complex punching matrices, with the help of which sheet metal is formed; reference gears; rolling dies; portages; matrices; punches. forged steel x12mf What ensures density? The high performance of X12MF steel, the characteristics of this grade are achieved by forging blanks. During the procedure, a round steel bar taken for processing is placed in a special forge. There it is heated to a certain temperature. After that, the Kh12MF bar is processed mechanically using a hammer. The result should be a strip of steel with a very high density. Then it is again placed in the hearth and subjected to heat treatment. After the strip has warmed up enough, it is cut into several small pieces. knives made of steel x12mf reviews In the future, by processing, they are given the desired wedge-shaped shape. In this way, knives are made from Kh12MF steel. The owners' comments about such blades are mostly positive: the structure of the steel of the blanks becomes very dense during their processing with a hammer, and this, in turn, provides the blades with high resistance to blunting. Why do we need alloying elements? In its original form, any steel is an ordinary alloy, which includes iron and carbon. Depending on the task that the product will perform, a chemical change of the alloy is carried out, and this, in turn, improves and adapts Kh12MF steel. The characteristics (reviews confirm the information) of the improved material are as follows: high strength; increased corrosion resistance; durability of operation; high cutting ability. Kh12MF acquires these qualities as a result of adding alloying elements to it. The procedure is carried out in a certain temperature regime with the required number of hardenings.

Characteristics and application

X12MF steel is a high-alloy (high-chromium) semi-heat-resistant tool steel of high hardness with increased wear resistance. This steel is widely used for the manufacture of cold dies and other tools that deform metal in a cold or relatively low heated state. Most high chromium forged steels contain an average of 12% chromium (Cr) and a high percentage of carbon. This leads to the formation of a large amount of chromium carbides (Cr7C3).

It is a large amount of the carbide phase (under all modes of heat treatment) that makes the steel highly wear-resistant.

Steel Kh12MF also has good ductility and grindability.

The required high hardness of X12 type steel can be obtained by hardening

from high temperatures (1150 °C) in oil and thus obtaining a large amount of retained austenite, and then by cold working and tempering

achieve decomposition of retained austenite and obtain high hardness (>60 HRC).

But more often steel type X12 is quenched from temperatures that give the greatest hardness.

after hardening (from 1050-1075 °C) and subsequent low tempering (at 150-180 °C).

The hardness is the same in both cases (61-63 HRC), but in the first case the steel

has a higher red hardness, and in the second - greater strength.

The hardness of Kh12MF steel reaches its maximum value (61-63 HRC) after hardening from 980-1020 °C; At the same time, the steel retains a grain of 10 and 15-20% of austenite (which is more than that of many non-heat-resistant steels).

With an even greater increase in the quenching temperature, the hardness decreases from 50-55 HRC and below due to a sharp increase in the amount of austenite. With an increase in heating temperature >1000-1020 °C strength also decreases due to grain growth and the influence of austenite.

The elastic limit of steel Kh12MF (for hardness 56-57 HRC)

Steel Kh12MF is little deformed during hardening, and when using thermal finishing, the deformation can be reduced to almost zero. Therefore, this steel should be recommended for a tool of complex shape, for which deformation during hardening is unacceptable.

The toughness of Kh12MF steel after quenching for fine grain (from 1025 ° C) and tempering at 200 ° C (58-60 HRC) is 0.28-0.3 MJ / m 2 in the longitudinal direction for rolled products with a diameter of 16 mm and 0.26 and 0.16 MJ / m 2 for rolled products with a diameter of 40 and 125 mm, respectively. In the transverse direction, it is even lower: 0.11 and 0.07 MJ/m 2 for rolled products with a diameter of 40 and 90 mm.

Molybdenum and vanadium in Kh12MF steel are necessary additives; they contribute to the preservation of fine grains and increase strength and toughness.

X12MF steel is used for cases where a higher toughness is required than that of steel grade 12X - for the manufacture of cold dies of high abrasion resistance (mainly with a rounded working part), not subject to strong shocks and shocks, drawing boards and dies, eyes for calibrating bar metal for thread rolling, bending and forming dies, complex sections of body dies, which during hardening should not be subjected to significant volumetric changes and warping, dies and punches for punching and punching dies, stampings of the active part of electrical machines and electromagnetic systems of electrical apparatus.

For the manufacture of profiling rollers of complex shapes, sections of body dies of complex shapes, complex hole-piercing dies when forming sheet metal, reference gears, knurling dies, drawing dies, dies and punches for punching, punching dies (including combined and sequential ones) with a complex configuration of working parts, stampings of the active part of electrical machines.

GOSTs and TUs for Kh12MF steel

GOST 1133-71 "Forged round and square steel. Assortment";

GOST 4405-75 "Hot-rolled and forged strips from tool steel. Assortment.";

GOST 5950-2000 "Rods, strips and coils of alloyed tool steel. General specifications.";

GOST 14955-77 "Quality round steel with special surface finish. Specifications.";

GOST 2590-2006 "Steel hot-rolled round bars. Assortment.";

GOST 2591-2006 "Hot-rolled square section steel. Assortment.";

GOST 7417-75 "Sizing round steel. Assortment.";

GOST 4405-75 "Hot-rolled and forged strips from tool steel. Assortment.";

GOST 8559-75 "Square calibrated steel. Assortment.";

GOST 8560-78 "Calibrated hexagonal rolled stock. Assortment.";

GOST 1133-71 "Round and square forged steel. Assortment.";

TU 14-11-245-88 "High precision shaped steel profiles. Specifications.";

No questions about this product, be the first and ask your question.