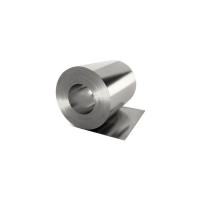

Brake tape LAT-2 is made from asbestos fiber intertwined with brass wire and impregnated with an oil emulsion. Thanks to wire reinforcement, asbestos tape acquires greater strength while maintaining its elastic qualities. This tape is needed to maintain the required friction force in friction and braking devices of the belt and shoe type of various mechanisms.

Reliable operation of asbestos tape is carried out at temperatures above +280 ° C and at a pressure not exceeding 5 MPa.

They are used as linings in brake and friction units of machines and mechanisms with a surface friction temperature of up to +300 °C.

Tape brand LAT-2 - oil-impregnated, operating at pressures up to 5 MPa (50 atm) and dry friction.

Physical and mechanical parameters:

Dry friction coefficient for cast iron grade SCh 15 - 0.45 ÷ 0.60

Linear wear, mm, no more than for cast iron grade SCh 15 - 0.11

Increase in mass when exposed to water and oil,

%, no more, with thickness:

from 4 to 5 mm inclusive – 8

over 5 to 8 mm inclusive - 12

over 8 mm - 14

Density, g/cc. — 1.45 ÷ 1.65

Crushing strength - 10

Flexural stability - no cracks or broken threads

LAT 2 woven brake tape (asbestos brake tape) is used as linings in brake and friction units operating at pressures up to 5 MPa and surface friction temperatures up to 300 °C.

The brake band is reinforced with brass wire. To work in areas with a tropical climate, the LAT brake band is made using fungicides.

Our company sells asbestos products for the manufacture and repair of various equipment and individual components. You can buy certified products with delivery throughout Ukraine.

Brake band LAT-2

It is one of the most common types of such products. The material is produced by weaving asbestos threads using oil impregnation; to increase strength, reinforcement is performed with brass wire.

The material is intended for use in a wide temperature range, with a maximum surface friction temperature of +300 °C. The brake band can withstand dry friction pressure up to 5 MPa. The product has a long service life - up to 7 years after the date of manufacture. Scope of application of the brake band.

The material is used in many industrial sectors - instrument making, mechanical engineering, etc. The products are in demand in the form of linings for friction and brake units of mechanisms and machines. The brake band retains its properties for a long time; cracks and broken threads do not form on it.

The brake band is available in thicknesses of 4 – 12 mm, and the width can vary in the range of 13 – 200 mm. The product is subjected to factory tests in terms of dry friction, linear wear, weight gain when exposed to water and oil.

Brake bands, their types and characteristics

All existing principles of mechanical and electromechanical braking of various mechanisms and units determine the use of brake elements. Despite the design diversity of brake systems, the most effective is the use of friction tape material. The use of high-quality brake tape predetermines

The degree of heating and wear of structural elements of the brake assembly;

Intensity and smoothness of the braking process;

Reliability and efficiency of brakes;

Precision stopping mechanism.

The brake tape is a consumable material and has high thermal and mechanical strength, wear resistance and durability and is actively used in numerous sectors of the national economy and industry, especially since it is produced in various variations and dimensions.

Characteristics of the LAT-2 brake band

Produced strictly in accordance with GOST. The brake-friction tape LAT-2 has an asbestos fabric base and is impregnated with oil compounds; the asbestos base contains reinforcing brass threads.

Designed for installation as brake/friction pads in mechanisms and components.

Considering the significant scope of application, the brake-friction tape LAT-2 is produced unpolished, with a thickness of 4.0 ÷ 12.0 mm and a width of 13 ÷ 200 mm, and has a double-sided working surface, which greatly simplifies its installation and replacement.

Environmental parameters for brake band EM-1, EM-K

It is manufactured strictly in accordance with the requirements of GOST 15960-79 and also has an unpolished surface. Elastic asbestos rubber brake-friction tape EM-1 is recommended for use in tropical/temperate/cold climates in open and closed dry friction brake units that create an internal pressure of less than 1.5 MPa and have a contact surface temperature of up to 200 C.

Brake-friction tape EM-1 is resistant to bending and provides a coefficient of friction interaction in the range of 0.39 ÷ 0.54 mm; Linear wear appears only upon contact with cast iron surfaces (less than 0.17 mm).

Produced in thicknesses of 5.0 ÷ 10.0 mm, widthlength 50 ÷ 160 mm, measured length by a piece is determined by the customer.

A brake band is a device that is often included in a number of brake system designs. The strip itself is usually a flat strip of metal, smooth on top and rougher on the bottom. Typically, the brake band is circular in shape, forming a loop that can be tightened or loosened around the shaft. The friction created by tensioning the belt helps slow and eventually stop the rotation of this shaft.

The brake band is often used as part of the gear box hardware that is attached to the transmission. In this application, the strip often consists of steel. The underside is covered with some kind of friction material and the belt is placed around the drum of the equipment. As the gears pull the belt, the rotation of the drum slows down and stops.

Along with the band and drum, there are several other elements that make up the equipment of the brake band. Anchor is typically used to secure one end of the band to the transmission housing. This particular element helps to regulate the amount of clearance between the drum and the actual brake band. An element known as a servo piston is used to apply pressure to the belt, tightening or releasing the pressure of the belt around the drum. This helps maintain the integrity of the pressure being applied to the drum and helps control the function of the brake band. Some designs use additional hydraulic equipment to increase the efficiency of the pressure applied to the drum and belt.

This same basic idea is used in other applications. The chainsaw brake band allows you to adjust the speed of the saw teeth, quickly moving from maximum speed to a complete stop. Tractors used in commercial farming often use brake band equipment as part of the overall engine and transmission design. Even children's karts can use this relatively simplified design to control the speed of the device and bring it to a complete stop.

Disadvantages Rapid wear of parts belongs to the weak points of band brake structures. Because of these problems, it is often necessary to carry out repairs. Other disadvantages include: uneven distribution of pressure on the arc of coverage; the complexity of calculating the force that bends the brake shaft; depending on which direction the pulley rotates; frequent damage to the steel tape. The last breakdown can lead to an accident due to a broken tape. The low operational reliability of tape mechanisms leads to the fact that they have recently been trying to replace them with shoe mechanisms. These brakes have a longer service life and wear out less quickly.

Advantages of 16k20 brake bands

Our products can withstand high loads and maintain their performance in various conditions:

able to withstand temperatures from -60 to +200°C;

has a high coefficient of elasticity, due to which it can be used in brake devices with different bending values of the rubbing surfaces;

Brake band 16k20, reinforced with wire, is specially impregnated with an oil mixture, thereby increasing its performance characteristics.

Brake band 1k62: scope

Due to the excellent dielectric properties of the asbestos from which the tape is made, they are used in various fields where it is necessary to withstand high temperatures, for example:

for thermal insulation in the manufacture of various heating devices;

in the manufacture of furnaces and steam boilers;

if necessary, lining thermal devices.

The company produces from asbestos not only 1k62 brake bands, but also other products necessary for production as consumables:

asbestos cardboard;

asbestos paper;

asbestos fabrics and cords;

asbestos gland packings, etc.

From us you can buy Brake Tape LAT-2 at the best price in Ukraine. A wide range of products allows us to quickly and efficiently fulfill any orders, helping to complete any construction work on time.

No questions about this product, be the first and ask your question.