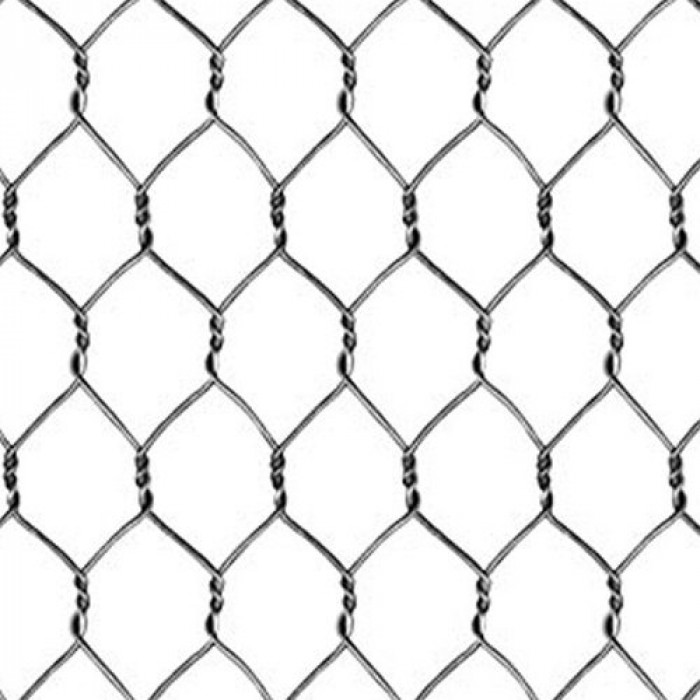

Manyer steel mesh 40х1,4 mm is a metal product made of wire with a hexagonal cell, which is made by twisting adjacent spirals with intertwined wires or mutually twisted at an angle of 120 degrees.

The cell size of the twisted mesh with hexagonal Magnier cells is from 10 to 100 mm (the cell size is the shortest distance between the twists);

Magnier mesh is woven from low-carbon heat-treated wire (not galvanized, galvanized, polymer-coated) with a diameter of 0.9 to 2.3 mm.

The main difference between the manyier mesh and other steel wire meshes is that even if one cell is damaged, the canvas remains intact.

This property is very important in the production of gabions and Reno mattresses. After all, if you make gabions from the Rabitz mesh, then when one wire breaks, the gabion is torn apart like a stocking and the stones spill out.

For builders, the property of this grid is important not to change the geometry of the cell in the set solution. The design of the manyier mesh ensures uniform distribution of loads in the plaster layer. As the temperature increases and decreases, the cell size changes along with the temperature changes in the layer. Only manyier mesh and woven mesh have this property.

Magnier mesh is a product with hexagonal cells, made of low-carbon steel, heat-treated or galvanized wire. To obtain a hexagonal mesh, two adjacent, parallel wires are connected by alternating single or double twisting at an angle of 120 degrees. As a result, a lattice fabric with hexagonal cells resembling a honeycomb is formed. It is possible to obtain products with rhombic and trapezoidal cells.

Production, characteristics, types and other aspects of twisted mesh are regulated by GOST 13603-1989. Grids wire twisted with hexagonal cells. Specifications. To purchase products that meet the characteristics, it is recommended to make a purchase in companies whose employees are able to provide documents confirming the quality, in particular, a certificate of conformity and a passport.

Production

Magnier mesh production technology consists in twisting the wire at an angle of 120 degrees. The fabrication process includes wire feeding, weaving and creating mesh rolls. The length of the twist in accordance with GOST should not be less than 1 cm. In this case, cells of a hexagonal, less often rhombic or trapezoidal shape are formed. The choice of the lattice structure of the canvas and the hexagonal shape of the cells is not accidental. Such cells provide efficiency in distributing significant horizontal in-plane stress.

Characteristics of wire materials

The main characteristics of twisted meshes are presented in the current state standard 13603-89:

Grids are made from low-carbon heat-treated wire without coating or galvanized groups L and C in accordance with TU 14-4-1563.

The surface must be clean and free of dirt and rust.

The mesh should not contain broken and non-twisted wires. Splicing of the ends with an extension, twisting or welding is allowed.

The length of the twist or extension should not exceed 10 mm, the number of closed gaps that change the shape of the cell should not exceed one per 10 meters of length.

Grid with a cell of 100 from a wire with a diameter of 0.6 mm. to strengthen the edges, it can have bead wires of a larger diameter.

The mesh is produced in one piece, rolled into a roll with a length of over 50 meters and a weight of up to 80 kg. By agreement between the consumer and the manufacturer, it is allowed to produce rolls weighing up to 200 kg.

Advantages and disadvantages, features of double torsion materials

The main feature of the twisted mesh is the production technology that allows to obtain unique hexagonal cells that contribute to the distribution of horizontal stress throughout the wire cloth. The use of heat-treated wire and the specific way of twisting it ensures the elasticity of the mesh, which increases the strength characteristics and mechanical properties, and also allows the use of fabrics for working with surfaces with complex configurations: angular and curved. In addition, it is possible to note the priority advantages:

affordable cost;

aesthetic appearance;

maintaining integrity when one of the wires breaks;

flexibility, plasticity and elasticity;

strength, and, accordingly, a long service life;

the absence of notches and protruding elements ensures complete safety of working with the mesh, the risk of injury is practically excluded;

ease of working with the grid, regardless of the type of tasks performed;

multifunctionality, the ability to successfully perform a wide range of tasks in various fields of activity.

even a mesh made of small-diameter wire does not tangle in a roll;

compact size (dia.etr) rolls, which saves on transportation and storage;

a wide range of types and sizes.

It is difficult to point out any shortcomings. High-quality products meet all the characteristics and advantages, successfully perform their own functions and provide the desired result.

Metal/steel, hexagonal mesh and other types

Clients are provided with a fairly large number of types of the Manye grid:

According to the type of surface, uncoated products are distinguished, i.e. made of low-carbon wire without coating (designation - “n / u”), galvanized (“ots”) and with a polymer sheath (“PVC”).

According to the manufacturing accuracy, there are grids of normal and increased accuracy.

Depending on the diameter (thickness) of the wire. In accordance with GOST, for the production of Manye it is possible to use a wire with a diameter of 0.6; 1.3 and 1.6 mm. But on sale, customers have the opportunity to find products made of wire and a larger diameter.

In accordance with the size of the cells, several varieties are distinguished. According to GOST, the nominal cell size is 25, 50 and 100 mm. But in practice, manufacturers provide a much larger selection of products. The canvas can be made of regular or elongated cells.

depending on the shape of the cells. The traditional option is a grid with hexagonal cells, but there are also rhombic and trapezoidal.

It is possible to classify meshes depending on the size of the rolls, the length of which, in accordance with GOST, is at least 50 meters, and the width varies from 500 to 2000 (rarely 3000) mm.

Numerous advantages ensure the demand for the Magnier grid, which is used to solve an extensive list in various fields of activity.

For sports fields

When choosing a budget solution for decorating sites for various purposes, chain-link was often preferred, because. it is the most affordable option. But the woven mesh has some disadvantages that are not inherent in Manyer. Therefore, for the construction of fences for sports and playgrounds, polymer-coated twisted mesh is increasingly used, which has optimal indicators of wear resistance, aesthetic appearance and cost in comparison with analogues. Manye prefer to choose the grid for the design of sports fields for several reasons:

After cutting the wire, the product retains its integrity, which simplifies the preparation for installation, it is possible to cut a sheet of any size without worrying about its destruction.

High resistance to deformations, the mesh can withstand loads up to 3500 kg, which ensures high anti-vandal performance, and, accordingly, long-term operation.

The density of the anti-corrosion coating. The class of galvanizing is 3 times higher in comparison with the performance of the chain-link.

The flexibility of the fabric allows you to form fences of various, including complex shapes without additional difficulties, which is impossible when working with rigid welded structures.

For cable laying, OKL

The use of fire-resistant cables in warning and evacuation systems, i.e. in fire protection complexes, has long been a mandatory norm. But the “cable + cable duct + fastening” solution, called the fire-resistant cable line (FCL), has been used relatively recently. The lines are used to transmit electricity to emergency systems of ventilation, warning, navigation, lighting of evacuation routes, etc. OKL can consist of 1 or several cables, cable support system and fasteners. OKL are mounted in groups and singly. For the installation of lines, the Manye mesh is used, in which fire-resistant cables are laid. The mesh is attached to the wall with anchors or hooks.

For fences, fences

The affordable cost of the Manye mesh makes it an excellent solution for erecting fences and fences around a private area, primarily for decorating summer cottages. Ease of installation and the possibility of using various methods of fastening makes it possible to independently build a barrier structure, which reduces financial costs. Aesthetic appearance and harmonious combination with both green spaces and stone jungle make Manye an excellent option for landscaping city parks, squares, and gardens. Manye is also suitable for arranging fencing of industrial and industrial territories, warehouses, sports stadiums, various urban infrastructure facilities, in particular, parking lots. For the construction of temporary structures, it is possible to use an uncoated wire mesh. For durable structures, a galvanized or polymer-coated mesh is used.

You can buy a steel mesh manye 40х1,4 mm from us at the best price in Ukraine. A wide range of products allows us to quickly and efficiently fulfill any order, helping to complete any construction work on time.

No questions about this product, be the first and ask your question.