Tape (foil) brass L63t 0.1x200 mm due to the properties of alloys, has a high resistance to corrosion and is easy to machine.

Widely used for the manufacture of small parts of various shapes in many industries. Used to create relays, capacitors, bearings, non-wire resistors and other radio components.

Used for various design solutions in the interior, electromechanics, electrical engineering, auto electrics.

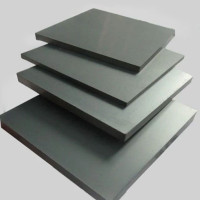

Brass foil - a rectangular strip made of an alloy called brass. This product, along with the brass strip, is one of the thinnest products obtained by rolling. The thickness of the brass foil can vary from 0.015 to 1 mm. In special cases, according to customer requirements, it is possible to obtain foil with a thickness of 0.004 mm.

The range of rolled metal obtained from copper-based alloys is quite extensive. The most common are brass tape and foil.

Classification and characteristics of brass foil

Brass has higher corrosion resistance and strength compared to copper. The foil made of brass has a high resistance to aggressive environments. The thermal and electrical conductivity indices for this foil remain low.

Brass foil is a brilliant aesthetic material with many applications.

Distinctive features of brass foil:

• has small weight;

• high strength;

• the material is completely safe for the environment;

• easy to process;

• resistant to corrosion.

The anti-corrosion properties of brass foil are especially good in air, sea climate, fresh water, in the presence of dry gases, halogens, and dry steam. A fairly wide range of environments in which brass foil can be used makes it a sought-after material on the market.

You can buy brass foil in special rolls, in which it has been rolled up for easy storage and transportation. The width of the rolls can be from 10 to 480 mm.

Brass foil, depending on the material from which it is made, can be classified into the following groups:

• Extra hard - (O).

• Hard foil - (T).

• Semi-solid - (P).

• Soft - (M).

If necessary, the foil can be cut into pieces of predetermined sizes. It cuts without much effort, leaving no torn edges and burrs that can adversely affect performance.

Brass foil has a special adhesive layer. With which it can be easily glued to the desired surface. You can stick the foil either manually or using special tools.

Production of brass foil

Brass foil is produced in accordance with GOST 15527-2004. GOST 2208-2007 regulates the production of cold rolled brass foil for general purposes. Since the cold rolling method is used in the production process, the letter X is present in the marking. The hot rolling method is not used for the production of foil, due to the fact that brass loses ductility when heated.

Most often, brass alloys LO90-1, L90, L80, L68 or LS59-1 are used for the manufacture of foil. To obtain a foil with increased hardness, an alloy of the L63 brand is used. Because of its good ductility, brass foil can be rolled to a thickness of tenths of a millimeter.

Brass foil is made in accordance with the requirements of this standard from brass grades L90, L85, L80, L70, L68, L63, LS59-1, LO90-1, LO62-1, LMts58-2, LZhMts59-1-1 with a chemical composition according to GOST 15527.

The surface of the foil must be free from contaminants that hinder inspection. Tempering colors, local darkening, traces of technological lubricant, as well as local defects are allowed on the surface, which do not remove the foil during the control cleaning beyond the limit deviations in thickness.

The foil must be straight cut and free from burrs that would significantly affect the intended use of the foil. Wrinkled and torn edges are not allowed. Slight waviness is allowed, disappearing at the control bend.

Brass foil is quite widespread in industrial production and as a finishing decorative material. Quite often, brass foil is used to replace gold plating and gilding. The brass foil plating looks practically the same as gold. At the same time, the cost of brass coating is ten times cheaper. Soft brass foil has found application in the manufacture of bench models of various configurations, electrical parts and decorative items for various purposes.

Due to its physical and mechanical properties, brass foil has found wide application in a variety of industries:

decorative and finishing works;

production of stained-glass windows;

production of electrical devices;

making jewelry and bijouterie.

This rolled product is well suited to imitate gold plating, due to the color of the metal. This featureb is used when creating the effect of gilding on jewelry, sculptures, decoration, etc.

Brass foil L63 is made by rolling brass brand L63. This brand of brass is a copper-based alloy with zinc as the main alloying element. This alloy lends itself well to deformation by pressure, well polished, well amenable to welding and soldering. Possesses the raised mechanical indicators and reasonable price in the market.

You can buy Tape (foil) brass L63t 0.1x200 mm from us at the best price in Ukraine. A wide range of products allows us to quickly and efficiently fulfill any order, helping to complete any construction work on time.

No questions about this product, be the first and ask your question.